The mineral insulated cable is composed of a high conductivity copper conductor, mineral (magnesium oxide) insulation and a seamless copper tube sheath. When the cable is used for corrosion of copper, the outermost layer can be coated with a plastic jacket. (optional). The bare cable has a continuous working temperature of 250 ° C. It can be continuously supplied for 3 hours at 950 ° C ~ 1000 ° C. It can work close to the melting point of copper at 1083 ° C for a short time or very period (magnesium oxide melting point is 2800 ° C).

750V copper sheathed copper conductor mineral insulated cable BTTZ model specifications:

B----Fixed power cable for wiring

T----copper sheath

T----copper conductor

V/Y----outer sheath: polyvinyl chloride V, polyethylene Y

Z/Q----withstand voltage option, withstand voltage rating heavy duty 750V, light 500V

For example: WD-BTTYZ-750V-4×(1×95), expressed as: heavy four-piece 95mm2 single-core cable, covered with halogen-free low-smoke polyethylene sheath.

Rated voltage of mineral insulated cable:

Light load (BTTQ, BTTVQ, WD-BTTYQ) 500V

Heavy load (BTTZ, BTTVZ, WD-BTTYZ) 750V.

The test voltage of the finished product of mineral insulated cable; light load 2000V/1min, heavy load 2500V/1min.

The insulation resistance of mineral insulated cables should be greater than 1000MΩ. When the cable length is less than 100m, the insulation resistance should be greater than 10000MΩ.

1. Working temperature of mineral insulated cable:

The long-term working temperature of mineral insulated cable is 70 °C. The long-term working temperature of mineral insulated cable is 105 °C when it is not touched. In special high temperature, the long-term working temperature can be 250 °C or below. It can be continuously supplied for more than 3 hours at 950-1000 °C, and the working temperature can reach 1083 °C in short or very short time.

2. Mineral insulated cable life:

Since the cables are made of inorganic materials, they do not age and can be used for more than a few hundred years.

3. Greening and environmental protection:

The cable components are all inorganic and do not contain any organic matter. Therefore, even if the cable is heated at 1000 °C, it will not produce the slightest smoke, and no halogen or toxic gas. This cable is a safe product that can truly achieve green environmental protection.

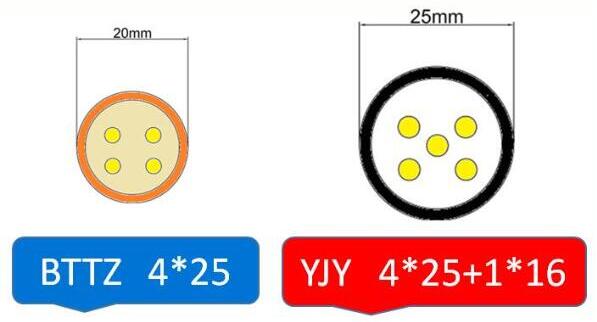

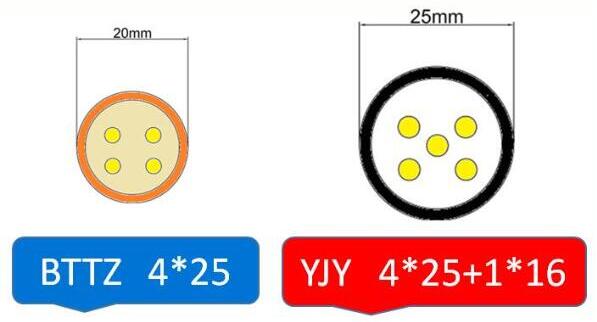

4, small outer diameter, light weight:

Compared with the flow-through plastic cable, the outer diameter and weight of the mineral insulated cable are much reduced, which can reduce the space and facilitate installation.

5, high mechanical strength:

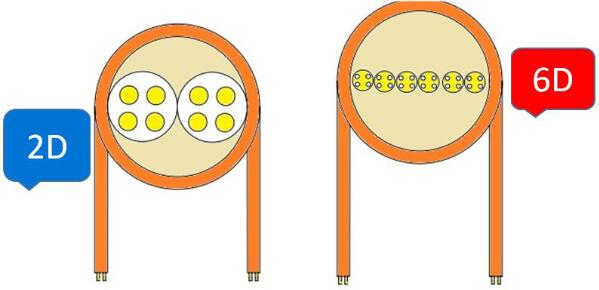

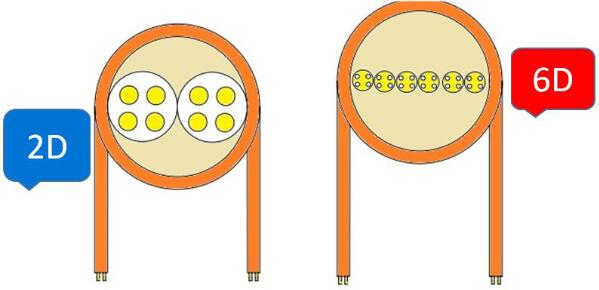

The cable structure is compact, durable and can withstand external force extrusion, impact, bending, flattening, etc., and can continue to be safely used when the cable is flattened to 1/3~2/3 of the original cable outer diameter.

6, the bending radius is small:

After the cable is fully annealed, it has a bendability comparable to that of a typical plastic cable. The minimum bending radius is only 2~6 times of the outer diameter of the cable. If you need to repeat the bending multiple times, you need to use the torch to heat the curved part to avoid cable breakage.

7, high working temperature:

Since the melting point temperature of the insulating layer magnesia is higher than the melting point temperature of copper, the maximum normal working temperature of the bare cable can reach 250 ° C, and the short-term operation can be continued at a temperature close to the melting point of copper of 1083 ° C.

8, fire, anti-corrosion, anti-riot:

Because the cable is sheathed with a seamless copper tube, the conductor, the insulation and the sheath are tightly pressed together, so that it not only protects against water, moisture, oil and some chemical substances, but also prevents flammable oil vapor and The spread of the flame.

9, good grounding:

For mineral insulated cables, a separate grounding wire is not required because the copper sheath of the cable acts as a grounding conductor and provides very low grounding resistance, saving one ground wire compared to organic cables.

10, cable cost-effective:

Cable price comparison in the same environment: Cables transmit the same current carrying capacity; mineral insulated cable copper sheath can replace ground wire (PE line).

Specification for construction of mineral insulated cable joints and intermediates:

When the cable length is not enough, the intermediate connector is required when two cables are required to be connected together.

Mineral insulated cable intermediate connector connection: Install the cable terminal connector at each end of the cable to be connected. The core wire is connected between the two cable terminals with a crimping tube. The brass bushing with internal thread is tightened on the card. Multi-core cable is required. Set of thermoplastic casing or ceramic column, single core cable can be set or not.