CEMS anti-corrosion and heat tracing sampling composite pipe is an important part of the environmental monitoring system. It is composed of a set of corrosion-resistant high-performance resin pipes supplemented by self-limiting temperature heating cables and compensation cables to form an inner core, plus an insulation layer, and then a resistance Flame-resistant polyethylene (PE) protective jacket is compounded. The automatic temperature limit function of the self-limiting temperature heating cable can ensure that a certain temperature is maintained in the sampling tube, so as to ensure that the collected sample is consistent with the initial value as much as possible, and finally ensure that the environmental protection monitoring system continuously and correctly collects the sample gas.

According to the actual conditions such as the composition and temperature of the sample gas, different materials can be selected for the sampling tube in the corrosion-resistant heat tracing sampling composite tube, such as PFA (tetrafluoroethylene and perfluoroalkyl ether copolymer), FEP (tetrafluoroethylene and Hexafluoropropylene copolymer), PVDF (polyvinylidene fluoride), PE (flame-retardant polyethylene), nylon 610, etc. The heating cable can be medium, low and high temperature heating cables, and compensation can also be added according to user requirements Wire, power cord, etc.

CEMS anti-corrosion and heat tracing sampling composite pipe is a composite body composed of a variety of devices, and multiple systems are combined on a limited section.

Sampling system: Various types and materials of sampling tubes can be combined: PFA, FEP, PE, nylon 610, 12, copper tube, 316SS, 304SS, etc.

Thermal system: high-efficiency thermal insulation, flame-retardant and light-weight thermal insulation layer; automatic temperature-limiting electric heating cable or constant power electric heating cable.

Power distribution system: It can be equipped with instrument signal cables, compensation cables and control cables to meet the needs of instrument display monitoring.

Safety system: adapt to different process conditions, shield and isolate each system with aluminum foil or metal wire mesh to achieve fire safety, anti-static, electromagnetic shielding, and some add waterproof membrane and enhance flame-retardant and anti-ultraviolet sheaths. The combination of multiple systems integrates multiple functions into one, simplifying complicated projects. It is a good guarantee for remote work and remote diagnosis of the system. The heat tracing system keeps the gas in the tube from condensing and keeps the measurement above the dew point, so the measurement accuracy can be guaranteed, creating conditions for the computerization of centralized control. The reinforced outer sheath can prevent crossover and damage due to other factors.

CEMS anti-corrosion and heat tracing sampling composite pipe Technical parameters of the product:

① Electrical indicators

(1) Low temperature self-limiting temperature heating cable: 15-35W/m (power at 10°C), medium temperature heating cable: 40-60W/m, high temperature heating cable: 50-70W/m, constant power heating cable: 10-50W /m;

(2) Rated voltage: 220VAC;

(3) The larger heating length is 100~150m;

(4) Equipped with a circuit breaker with a current value of 30A. If the length of the composite pipe is ≥50m, it should be equipped with a special automatic current limiter for self-limiting temperature heating;

(5) One loop of the heating system.

② Thermal index

(1) In the case of an ambient temperature of -20°C and a wind speed of 15m/s, the temperature inside the tube is maintained at 40-50°C.

(2) The sampling tube is resistant to corrosion by various acid and alkali media, with a compressive strength of 1.0Mpa without leakage.

(3) The sampling tube can work for a long time at a temperature of <200℃.

③ Installation index

(1) The smaller radius of curvature of the composite pipe is 0.5m

(2) Large continuous length 100~150m

(3) Lower installation temperature -10℃ (appropriate measures should be taken at -30℃~-40℃)

(4) Small fixed distance: 5m in the vertical direction and 2m in the horizontal direction

Note: It is strictly forbidden to twist and drag on the ground during construction, and the pipe head sheath is only allowed to be disassembled when the joint is installed.

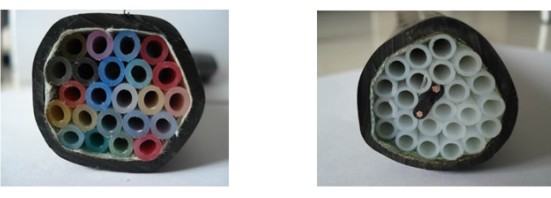

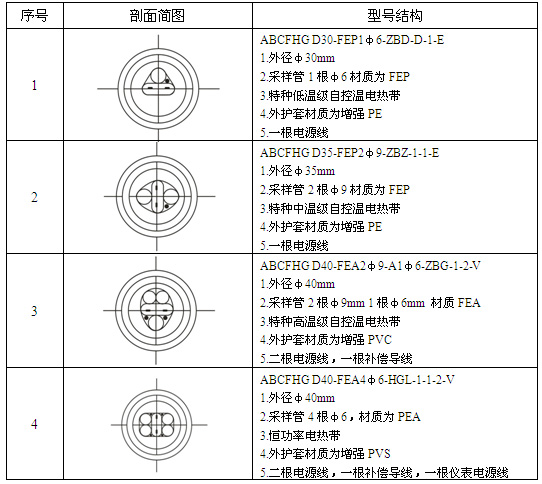

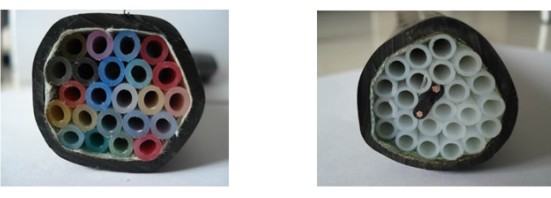

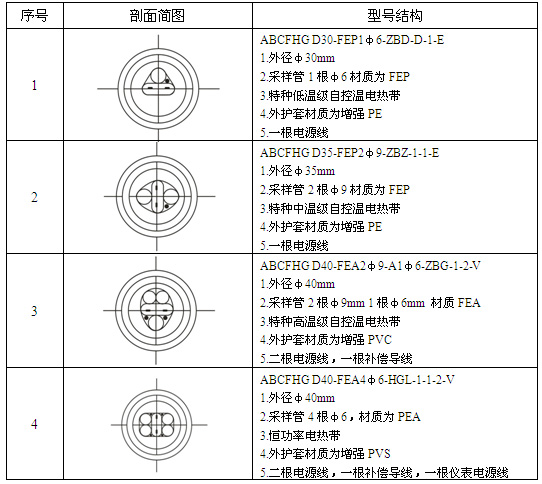

List of model, structure and section diagrams of part of the anticorrosive composite pipe for heat tracing sampling:

Note: A variety of special structure "composite pipes" can be customized according to the various requirements of users.

Note: A variety of special structure "composite pipes" can be customized according to the various requirements of users.